Nowadays, it’s rare when a videogame console manages to sell at a profit rather than a loss. Many of you may remember the days of when game consoles were priced as high as $500 simply because that’s how much they cost to build. It made absolutely no sense from a business standpoint to do otherwise. [shal]Sony[/shal], however, forever changed the playing field with their first game console, the [shal]PlayStation[/shal].

Though manufacturing costs were reportedly much higher, they ate the upfront losses (much to the horror of their competition) and attempted to make their money back through software licensing. It worked, and it worked very well. Sorry, [shal]Sega[/shal].

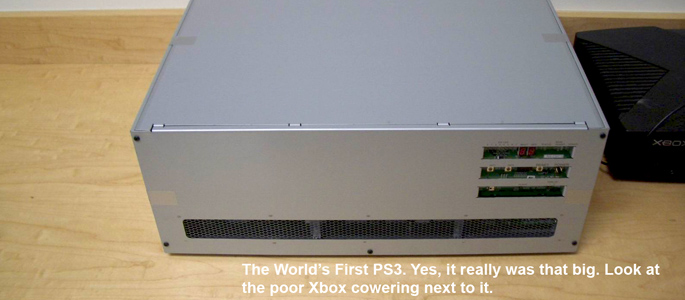

As with the PS1 and PS2, Sony is ensuring that the PS3, which cost over $800 to manufacture when it was launched in late 2006, will soon be profitable at retail. Based on information provided by Sony CFO Nobuyuki Oneda, PlayStation 3 costs roughly $420 to manufacture, which is a mere $40 loss when sold to retail. PS3s are sold for approximately $380, and tagged with an MSRP of $400.

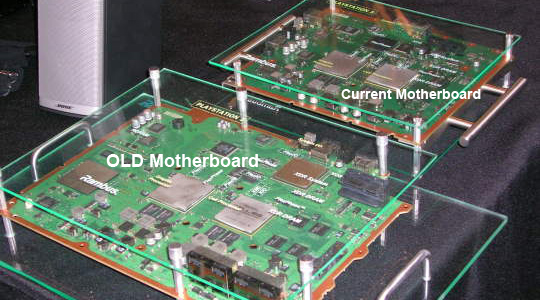

This is incredible, especially when you consider that Sony’s manufacturing geniuses have cut the console’s production costs by nearly 60% within the past two and a half years. As PS3 sales continue to climb, SCE’s profits should experience a significant boost, and it’s partially thanks to smart manufacturing. But as you may have heard, there may be even bigger drops in PS3 costs in the near future.